by Terry Wieland

It never fails. And when I say never, I mean never. I show up at the range with a shotgun with Damascus barrels, and at some point, someone is sure to mouth something like, “Them things is dangerous, ain’t they?”

Or, variations on the above, “You’re not going to shoot modern shells, are you?” Or, “I always read those blow up.” More than once, I’ve had someone refuse to shoot next to me on the trap line, or come anywhere near when we’re shooting Skeet. All of which is fine with me. Their loss.

Some years ago, Larry Potterfield, owner of MidwayUSA and a pretty knowedgeable gun guy, got interested in Damascus barrels and resolved to track the origins of the anti-Damascus fervor to its source. He eventually concluded that it began around 1930. Times were hard, ammunition and gun companies had merged (Winchester and Western, Remington and UMC, etc.) and the gun people were trying to sell guns.

Someone came up with the idea of persuading the shooting public that their old guns were not safe with modern, high pressure ammunition, and Damascus (or twist) barrels were the chosen fall guy. As the ammunition companies embarked on campaigns warning against the use of their ammunition in old guns, the gun companies ramped up their sales pitches for new steel alloy barrels.

All of this was aided and abetted by magazines that were suffering in the Depression and needed the advertising. It became an article of faith, and pretty soon grandfathers and fathers were advising their offspring against Damascus, and we all know that Grandad knew about these things and was never wrong.

My late dear friend and colleague, Michael McIntosh, was told this by his father and never let go of the belief, railing against Damascus in print until (almost) the day he died. Even when he got to know many of the English gunmakers, premier barrel makers, and English proof house personnel, and was presented with irrefutable proof of the value of Damascus, he could never shake off the dread. Even his pal, English gunmaker David Trevallion, could not convince him. The best Michael could manage was to stop shrieking in panic in the pages of Shooting Sportsman, and maintain a sulky silence.

There are many myths about Damascus.

One of Michael’s favorites was the idea that, as the rods of iron and steel were heated red hot and twisted and hammered into shape, moisture would hide in tiny caverns in the metal and eventually eat its way out, turning the barrels porous as Swiss cheese. Call me naïve, but I have never seen a bead of moisture survive very long on red-hot metal.

There is also the idea that the welds would weaken, eventually causing the hammered rods to spring apart. For the most part, writers just assumed that nothing old could be as good as something new, and that modern steel just had to be better.

Never mind that a test carried out by the proof house in England testing various types of barrels to destruction found the best to be a type of Damascus and second best the fluid steel of the day. This was more than a century ago, and undoubtedly nickel-steel and chrome-moly has its advantages, but that does not render Damascus useless. Another test indicated that Damascus will bulge where steel will break, and that bulged Damascus can be repaired.

There are other advantages, such as strength for weight, and how a Damascus gun can be exquisitely balanced, but those become rather esoteric and subjective. Here we are dealing with safety, pure and simple. To quote Edwin von Atzigen, my Swiss gunmaker and gun restorer of old, “a good barrel is a good barrel” and as long as pressures are kept within the limits dictated by the regulating authorities, there should be no problem.

Where steel has an insurmountable advantage is cost, and this is partly because the knowledge and skills to produce the fine Damascus that came out of Belgium 125 years ago no longer exists. Even if we wanted to make Damascus like that today, and were willing to pay for the man-hours, we couldn’t.

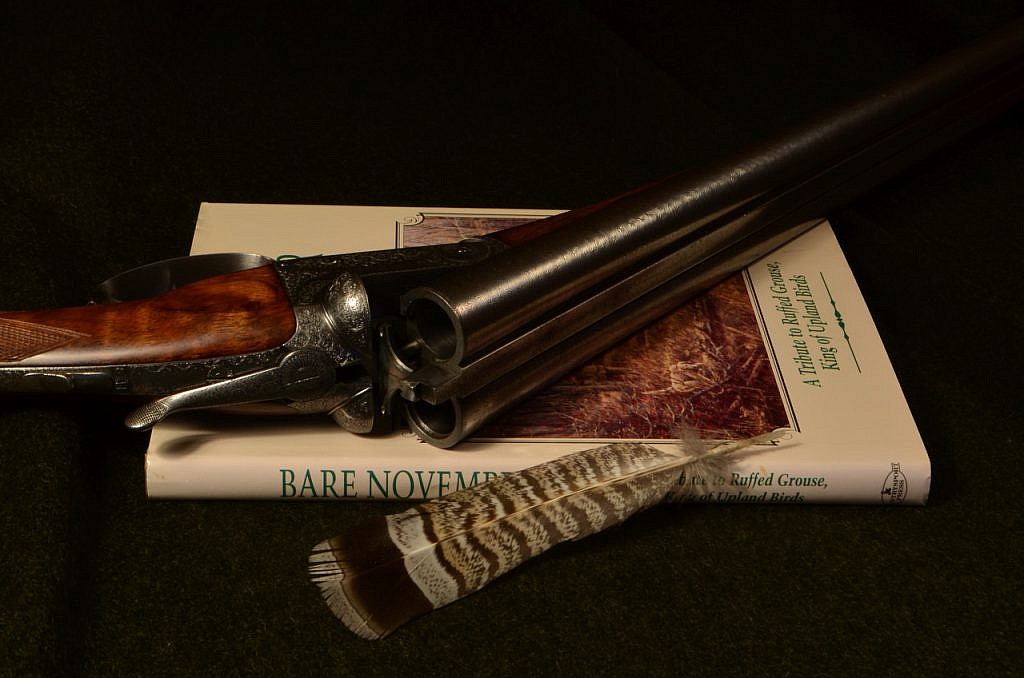

We can, however, still admire those barrels they made back then. On the rack right now, I have half a dozen shotguns with Damascus barrels, and one double rifle. My most beautiful Damascus is the barrels on an E.M. Reilly that was salvaged after 35 years in the rafters of a henhouse, and which Edwin restored for me 20 years ago. It’s a 12-bore with 30-inch barrels, and weighs an exquisitely balanced 6 lbs., 4 oz. It has a second barrel set, made later with fluid steel, but I never use them. They add an ounce of weight—inconsequential—but somehow never feel as good.

Perhaps the feel is imaginary, or perhaps I’m just mesmerized by that lovely Damascus. Either way.

The aesthetics of shotguns have always been a prime concern for Gray’s shooting editor, Terry Wieland, who finds that even if he can’t shoot a gun very well, he can always admire it.